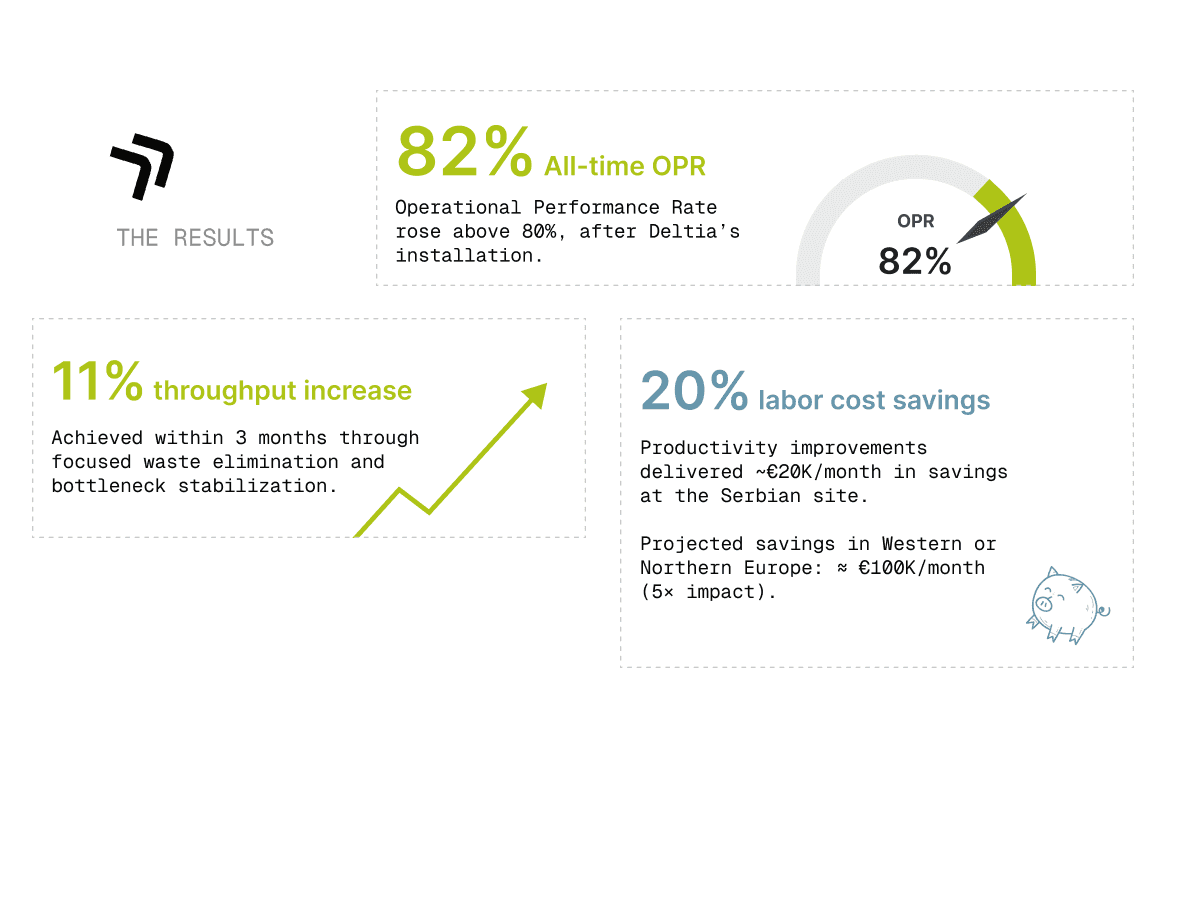

0%

throughput increase in 3 months

Grundfos x Deltia

What happens when the world's largest pump manufacturer uses AI to uncover what no one else could see?

Even high-performing lines eventually plateau. At Grundfos Serbia, a manual assembly line that had already gone through eight kaizens, tighter 5S, flow optimisation, and several redesign workshops still struggled to break through its efficiency ceiling. Operators were skilled. Processes were stable. MES was in place. But the numbers weren’t moving anymore and cost pressure was rising.

Despite clean MES dashboards and consistent output tracking, the real inefficiencies stayed hidden: micro-stops, missed steps, idle pockets, slowdowns too small or too frequent to record manually. This case study shows traditional tools could only reveal the tip of the Continuous Improvement iceberg.

What happened next became one of the most compelling examples of AI-driven process visibility in modern manufacturing.

Once the team could see clearly, they could act decisively.

This downloadable case study dives into the before-and-after reality of Grundfos’ transformation: what the team tried, why traditional tools weren’t enough, what AI exposed instantly, and how these insights translated into real, measurable improvements in productivity, quality, and labour allocation.

See the full breakdown of insights, visual analytics, AI-detected bottlenecks, and the exact steps the Grundfos team took to unlock 11 percent more throughput.

Technology

Use cases

Ready to unlock

hidden efficiency?

See how Deltia reveals bottlenecks and drives measurable improvements in just a matter of weeks.